D type and W type rubber fenders are two of the most prevalent and reliable solutions in marine fendering. While both serve the critical purpose of absorbing berthing energy, their distinct structural designs cater to different operational demands and vessel types. Understanding the characteristics and applications of D type and W type fenders is crucial for port engineers, shipowners, and project managers to optimize safety and cost-efficiency. As a leading rubber fender manufacturer, Tonly provides this in-depth comparison to guide your selection process.

Tonly's cylindrical rubber fender is renowned for its versatility and exceptional impact resistance. These fenders can be used in a wide array of marine applications, from small boats to large docking structures. The cylindrical shape allows for high energy absorption, distributing impact forces evenly to minimize stress on both the vessel and the docking structure.

One of the standout features of Tonly’s Cylindrical Rubber Fender is its durability. Made from high-quality rubber, these fenders are resistant to harsh marine conditions, including UV rays, saltwater, and abrasion. Their long lifespan ensures a cost-effective solution for port operators and ship owners alike. With easy installation and low maintenance requirements, the Cylindrical Rubber Fender proves to be a reliable choice for a broad spectrum of marine activities.

The d type rubber fender from Tonly is designed with performance optimization in mind. Its unique 'D' shape is engineered to offer maximum energy absorption and enhanced reaction force. This makes it particularly suitable for berths, piers, and marinas where robust protection is paramount.

Tonly's D Type Rubber Fender is not only efficient but also user-friendly. Its flat back facilitates straightforward installation against both flat and curved surfaces, making it adaptable to various docking configurations. Additionally, the compact design requires less space, making it ideal for locations with limited room, especially when installing rubber fender D-type systems. The D Type Rubber Fender's ability to provide dependable protection while conserving space underscores its innovative design.

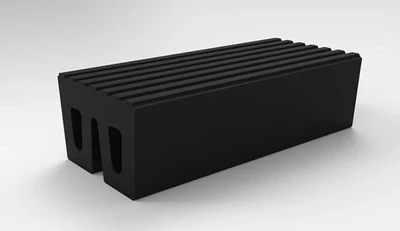

For harsh environments and demanding applications, Tonly’s W Type Rubber Fender emerges as a top contender. The W shape, characterized by its multiple grooves and wide profile, allows for superior flexibility, enabling the fender to handle substantial impacts with grace. This design ensures high energy absorption while maintaining a lower reaction force, making it well-suited for large vessels and heavy-duty berthing operations.

The w type fender is crafted from premium-quality rubber materials, ensuring long-lasting performance even in rigorous conditions. The W rubber fender's robust construction is complemented by excellent resistance to wear and tear, standing up to repeated impacts without compromising on protective capabilities. By choosing Tonly’s W Type Rubber Fender, operators can benefit from a reliable and sturdy fender system that supports safe docking maneuvers.

Choosing the right fender system is essential for safeguarding marine vessels and infrastructure. Tonly offers a comprehensive range of fender solutions—including the Cylindrical Rubber Fender, D Type Rubber Fender, and W Type Rubber Fender—each designed to meet specific operational needs. With a focus on durability, performance, and ease of installation, Tonly's range of fenders delivers peace of mind and superior protection in every marine environment. Explore Tonly's offerings today and invest in their high-quality fenders to ensure optimal safety and efficiency for your marine operations.

All you need to know about marine rubber fenders?December 16, 2024What exactly are marine rubber fenders? For the ordinary person, it may seem weird to have so many weird-looking shapes hovering beside a port or harbour, unclear of what they are for. Even when a pe...view

All you need to know about marine rubber fenders?December 16, 2024What exactly are marine rubber fenders? For the ordinary person, it may seem weird to have so many weird-looking shapes hovering beside a port or harbour, unclear of what they are for. Even when a pe...view What is a Composite Rubber Fender? Key Benefits vs. Traditional Rubber FendersDecember 10, 2025Introduction: The Evolution of Marine FenderingIn the demanding world of marine infrastructure, where ports, docks, and vessels face constant impacts from waves, tides, and berthing operations, protec...view

What is a Composite Rubber Fender? Key Benefits vs. Traditional Rubber FendersDecember 10, 2025Introduction: The Evolution of Marine FenderingIn the demanding world of marine infrastructure, where ports, docks, and vessels face constant impacts from waves, tides, and berthing operations, protec...view Commonly used Ten types of rubber fendersDecember 16, 20241 GD type rubberl Smaller bottom width size, especially suitable for framed docksl High energy absorption and high reaction force.l High installation strength and long service life.2. Super Dru...view

Commonly used Ten types of rubber fendersDecember 16, 20241 GD type rubberl Smaller bottom width size, especially suitable for framed docksl High energy absorption and high reaction force.l High installation strength and long service life.2. Super Dru...view W-type rubber fender performance advantagesDecember 16, 2024W-type rubber fender application: usually fixed on the steel structure shock-proof board with bolts and nuts, there are exceptions, it is directly fixed on the cement wall of the wharf, shock-proof wo...view

W-type rubber fender performance advantagesDecember 16, 2024W-type rubber fender application: usually fixed on the steel structure shock-proof board with bolts and nuts, there are exceptions, it is directly fixed on the cement wall of the wharf, shock-proof wo...view