A damaged tug fender isn't just a cosmetic issue—it's a critical safety and operational risk. From reduced impact absorption to potential hull damage, a compromised fender can lead to costly downtime and repairs. Understanding your repair options is essential for maintaining operational efficiency. This guide from Tonly, a leading tug fender manufacturer, outlines four common approaches to managing fender damage, helping you decide between a quick fix and a professional solution.

Repair method

1. Use a sander to clean the damaged position of the repaired fender, clean the residue with a brush, then flatten the fender and apply glue.

2. According to the size of the overlap, place the repair material (suspended rubber cord cloth) horizontally and vertically, and put the outermost layer in the fender so that it can be applied to the middle of the rubber sheet (pure rubber sheet) and brushed.

3. Put the heating plate on the repair material, put the jack on the heating plate, and then lift the jack to the top of the mouth-shaped bracket.

4. Press the jack until it is pressed by hand.

5. Turn on the power and activate the start button on the control cabinet to start maintenance.

6. When the temperature is reached, the heating device automatically stops. After stopping, the temperature of the heating plate rises, then the temperature drops and drops below 80°C, and the repair is completed.

7. Remove the jack, remove the heating plate, and then repeat the above steps to repair the damaged fender.

How to improve the wear resistance of D-type rubber fender?December 16, 2024The method to improve the wear resistance of Type D rubber fender is as follows:a. Choose polyurethane rubber, natural rubber, butadiene rubber, styrene butadiene rubber, neoprene rubber, nitrile rubb...view

How to improve the wear resistance of D-type rubber fender?December 16, 2024The method to improve the wear resistance of Type D rubber fender is as follows:a. Choose polyurethane rubber, natural rubber, butadiene rubber, styrene butadiene rubber, neoprene rubber, nitrile rubb...view TONLY Participates International Tug & Salvage Community 2025March 11, 2025TONLY Participates International Tug & Salvage Community 2025view

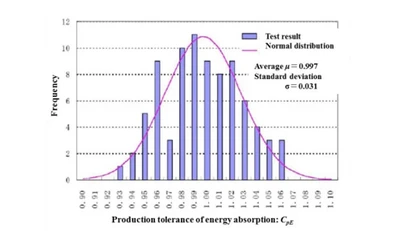

TONLY Participates International Tug & Salvage Community 2025March 11, 2025TONLY Participates International Tug & Salvage Community 2025view Performance of rubber fendersDecember 16, 2024In the design process, the performance of rubber fenders is considered in terms of deflection-reaction force characteristics in compression and the energy absorption calculated from these characterist...view

Performance of rubber fendersDecember 16, 2024In the design process, the performance of rubber fenders is considered in terms of deflection-reaction force characteristics in compression and the energy absorption calculated from these characterist...view Guidelines for the Maintenance of Rubber FenderDecember 16, 2024The marine rubber fender is a very important maintenance item in the ship's post. However, all ships sailing must be equipped with marine fenders, so as to ensure the personal safety of the person...view

Guidelines for the Maintenance of Rubber FenderDecember 16, 2024The marine rubber fender is a very important maintenance item in the ship's post. However, all ships sailing must be equipped with marine fenders, so as to ensure the personal safety of the person...view