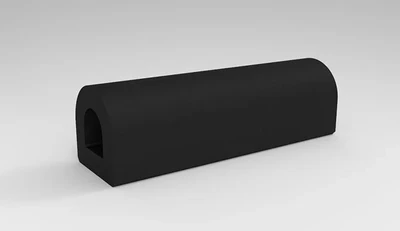

W-type rubber fender application: usually fixed on the steel structure shock-proof board with bolts and nuts, there are exceptions, it is directly fixed on the cement wall of the wharf, shock-proof wood, bollards, etc. Scope of application: It can protect the hull from the frictional impact between the dock and the hull, and protect the dock from direct impact damage from heavy ships.

First, the baffle panel increases the deformation range and absorption function in the case of reverse force. The absorption capacity (KN-M) has been increased from the original 167 to 200. The water absorption capacity has been increased. In the rolling fender series, the energy absorbed per unit weight increases.

Secondly, the front edge is equipped with a steel frame to reduce the surface pressure of the ship, which is especially suitable for the mooring of large ships. Due to the high energy absorbed by the reverse force of the device, it is particularly suitable for the needs of offshore terminals, especially docks.

Third, the PE plate can be installed in front of the fender to reduce the coefficient of friction and greatly reduce the shear force of the berth. From the stern to a certain length of the ship, the side outer panels in the vertical range of the freeboard deck are made of steel plates to prevent the hull side panels from colliding during berthing or mooring.

W-type fender and retaining rings are the products developed by our company in port terminals. Light weight, impact resistance, abrasion resistance, corrosion resistance, anti-aging performance, energy absorption and other properties, can prevent the impact of ultraviolet radiation and impact on the hull and dock. Fenders can prevent damage caused by collisions between ships and docks, are impact resistant, have a separate string, and rubber composite materials, and are widely used in major ports. At present, these schemes have been adopted by domestic and foreign ports. The fender is generous in appearance and can protect the vessel from wind and waves.

W-type rubber fenders are mainly used to protect docks and ports. It is mainly used to prevent the impact of ships on the dock. It has high impact resistance, impact resistance, very low water absorption, corrosion resistance and long service life. The quality of the fender veneer made of ultra-high polyethylene board can be used for several years or longer.

Cylindrical Rubber Fender & Dock: The Guardian of Marine SafetyOctober 17, 2024In the bustling world of maritime operations, the safety of vessels and docks is paramount. Enter the Cylindrical Rubber Fender & Dock—a robust protector designed to absorb the shocks and stresse...view

Cylindrical Rubber Fender & Dock: The Guardian of Marine SafetyOctober 17, 2024In the bustling world of maritime operations, the safety of vessels and docks is paramount. Enter the Cylindrical Rubber Fender & Dock—a robust protector designed to absorb the shocks and stresse...view The importance of vulcanization pressure for rubber marine fendersDecember 16, 2024The vulcanization pressure refers to the pressure per unit area of the rubber product during the vulcanization process. Except for thin-walled products such as tape, other rubber products require a ce...view

The importance of vulcanization pressure for rubber marine fendersDecember 16, 2024The vulcanization pressure refers to the pressure per unit area of the rubber product during the vulcanization process. Except for thin-walled products such as tape, other rubber products require a ce...view Stability of D-type rubber fenderDecember 16, 2024The quality of D-type rubber fenders always restricts production and use, interferes with docking and the safety of ship drivers, and affects the schedule of production ships. This is not an accidenta...view

Stability of D-type rubber fenderDecember 16, 2024The quality of D-type rubber fenders always restricts production and use, interferes with docking and the safety of ship drivers, and affects the schedule of production ships. This is not an accidenta...view Co-vulcanisation and dispersion with rubber fendersDecember 16, 2024At the same vulcanisation speed, general purpose rubber is fastest with natural rubber, followed by isoprene rubber, butadiene rubber, latex polybutadiene rubber and styrene butadiene rubber. Slow vul...view

Co-vulcanisation and dispersion with rubber fendersDecember 16, 2024At the same vulcanisation speed, general purpose rubber is fastest with natural rubber, followed by isoprene rubber, butadiene rubber, latex polybutadiene rubber and styrene butadiene rubber. Slow vul...view