UHMWPE fenders use ultra-high molecular weight polyethylene (UHMWPE) material, which has been widely used in the field of ship protection due to its excellent performance. Compared with traditional industrial marine fenders, UHMWPE fenders have many unique advantages, making them the first choice in modern ports and ship protection equipment. Let us take a closer look at the material characteristics of UHMWPE fenders.

UHMWPE fenders have excellent wear resistance and can effectively reduce wear during ship berthing and collisions. Its molecular structure gives it a very low coefficient of friction, which can effectively reduce the wear and tear between ships and docks. In addition, UHMWPE fender has strong impact resistance, capable of absorbing the immense energy generated during ship collisions, reducing the damage to ships and dock facilities.

Compared to traditional rubber or steel fenders, UHMWPE fenders show stronger corrosion resistance in marine environments. The uhmw fender can resist the erosion of seawater, salt, and other chemicals, maintaining their performance and appearance for a long time. At the same time, UHMWPE fenders also have excellent weather resistance, capable of withstanding extreme temperature changes and intense UV exposure, adapting to various harsh climatic conditions.

The low coefficient of friction of UHMWPE fenders reduces the frictional force with the fender during ship berthing, effectively lowering the shear force during berthing. This not only extends the service life of the fender but also protects the ship from excessive wear. The low friction also means a smoother berthing process compared to traditional industrial marine fenders, reducing stress on the ship and dock, and providing a safer berthing environment.

As an environmentally friendly material, UHMWPE fenders do not contain harmful substances and meet modern environmental protection requirements. During use, they do not release toxic gases or cause pollution to the surrounding environment, aligning with the concept of green sustainable development, making them an ideal choice for port and ship facilities.

Compared to traditional industrial marine fenders, UHMWPE fenders are lighter and easier to install, effectively saving labor and time costs. At the same time, they perform excellently in durability, reducing the need for frequent replacement and maintenance. UHMWPE fenders can be customized according to different needs, suitable for various types of port facilities, and have strong adaptability, greatly enhancing their value in practical applications.

A Kind of Full-Rotation TugboatDecember 16, 2024The full-rotation tugboat comprises a boat body, a main engine and a propeller, wherein circular rubber fenders are installed at a head, stern and middle part of the boat body;a V-shaped dead wood is ...view

A Kind of Full-Rotation TugboatDecember 16, 2024The full-rotation tugboat comprises a boat body, a main engine and a propeller, wherein circular rubber fenders are installed at a head, stern and middle part of the boat body;a V-shaped dead wood is ...view Unleashing the Power of Tug & Boat Rubber FendersOctober 17, 2024Tug & Boat Rubber Fenders are essential components in the maritime industry, providing critical protection for vessels during docking and maneuvering. Tonly Rubber, a reputable brand known for its...view

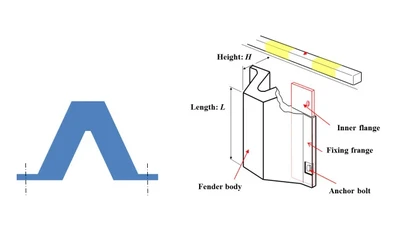

Unleashing the Power of Tug & Boat Rubber FendersOctober 17, 2024Tug & Boat Rubber Fenders are essential components in the maritime industry, providing critical protection for vessels during docking and maneuvering. Tonly Rubber, a reputable brand known for its...view Rubber fenders without fender panelsDecember 16, 2024V-type rubber fenders are considered as rubber fenders without fender panels. A V-type rubber fender has a V-shaped cross section with steel plates embedded in the fixing flange portion for installati...view

Rubber fenders without fender panelsDecember 16, 2024V-type rubber fenders are considered as rubber fenders without fender panels. A V-type rubber fender has a V-shaped cross section with steel plates embedded in the fixing flange portion for installati...view Stability of D-type rubber fenderDecember 16, 2024The quality of D-type rubber fenders always restricts production and use, interferes with docking and the safety of ship drivers, and affects the schedule of production ships. This is not an accidenta...view

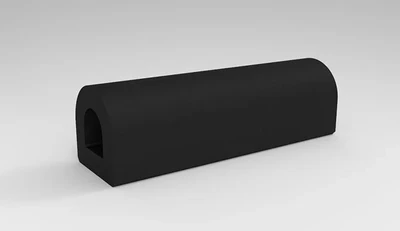

Stability of D-type rubber fenderDecember 16, 2024The quality of D-type rubber fenders always restricts production and use, interferes with docking and the safety of ship drivers, and affects the schedule of production ships. This is not an accidenta...view