When it comes to maritime safety, ensuring secure and efficient docking is a top priority. One of the key elements in safeguarding both vessels and docking infrastructure is the use of high-quality fenders. Arch rubber fenders, like the ones offered by Tonly, are specifically designed to absorb impact and provide the necessary protection against the frequent docking forces that ships endure. In this article, we'll explore how Arch rubber fenders contribute to docking safety, offering vessels long-term protection and reducing the risk of damage during mooring operations.

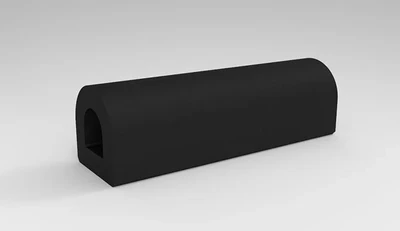

The primary function of Arch rubber fenders is to absorb and disperse the kinetic energy generated when a vessel makes contact with a dock or other stationary objects. The unique arch shape of the fender is engineered to offer exceptional impact absorption by providing more contact surface compared to traditional cylindrical fenders. This allows the arc fender to compress upon impact, effectively spreading the force across a larger area. The result is reduced localized pressure on both the vessel's hull and the docking structure, thus minimizing the potential for damage. The Tonly Arch rubber fender is built with high-quality materials that not only absorb the shock but also return to their original shape after the impact, ensuring long-lasting protection.

When a ship docks, it can experience a range of impacts, from gentle mooring to rough collisions, especially in busy ports with high traffic. The Arch rubber fender is designed to handle these various docking conditions by providing uniform protection across the hull. Its reliable shock-absorbing capabilities make it particularly useful in environments where large vessels or ships are constantly docking and undocking, reducing wear and tear over time.

Arch rubber fenders are particularly advantageous in high-traffic ports where multiple vessels dock frequently. In such environments, the repeated impacts from docking can create significant stress on both the vessels and the dock structures. With their superior ability to absorb and dissipate energy, arc fenders help mitigate the damaging effects of these repeated collisions. The fender's arch design allows it to maintain structural integrity even after frequent impacts, ensuring that ships remain protected regardless of how often they dock.

In ports with heavy vessel traffic, maintaining the safety of both the vessels and the dock infrastructure is crucial. Tonly's Arch rubber fender is specifically designed for such demanding conditions, providing consistent performance over time. By absorbing the kinetic energy from docking, the fender helps prevent costly damage to vessels and keeps the dock system in good condition. This is especially important for commercial ports, where downtime and repair costs can be significant.

Docking accidents can result in costly repairs for both the vessel and the dock. The role of Arch rubber fenders is crucial in preventing such damage, extending the lifespan of both the boat and the dock structure. With their ability to absorb shock effectively, arc fenders prevent dents, scratches, and cracks that can occur when a vessel is improperly docked or when forces are not properly distributed during docking. The high durability of the Tonly Arch rubber fender ensures that even with frequent use, the fender remains reliable, significantly reducing the maintenance costs associated with dock and vessel repairs.

As fenders are exposed to harsh marine conditions, including saltwater, UV rays, and fluctuating temperatures, durability becomes an important factor. Tonly's Arch rubber fender is made from high-quality materials designed to withstand these environmental stressors, ensuring that it remains effective for many years. This makes it a cost-effective solution in the long run, as it reduces the need for frequent replacements and repairs.

The Arch rubber fender offers several advantages when compared to other traditional fender types, such as cylindrical fenders or foam-based fenders. Below is a comparison table highlighting key differences in performance and suitability:

Feature | Arch rubber fender | Cylindrical Fender | Foam Fender |

Impact Absorption | High – absorbs energy effectively, especially for high-impact scenarios | Moderate – offers limited compression and impact absorption | Low – absorbs impact less efficiently |

Durability | High – resistant to wear, UV, and saltwater, designed for long-term use | Moderate – prone to wear over time, especially in harsh conditions | Low – can degrade in harsh marine environments |

Flexibility | Excellent – adapts well to various vessel shapes and docking conditions | Low – rigid, offers less adaptability | Moderate – compresses but does not have the flexibility of rubber |

Maintenance | Low – requires minimal upkeep due to its durable nature | Moderate – requires occasional inspection and maintenance | Moderate – needs regular checks and maintenance |

Installation | Easy – quick installation with versatile mounting options | Easy – straightforward installation | Moderate – requires special attention during installation to prevent wear |

From the comparison table, it's clear that Arch rubber fenders excel in providing higher impact absorption and durability compared to other fender types. Their ability to adapt to different vessels and docking conditions, coupled with their long lifespan, makes them a superior choice for high-traffic docking environments.

In conclusion, Arch rubber fenders play an essential role in ensuring docking safety by absorbing impact, protecting vessels, and preventing damage to docking infrastructure. Their unique design, built from high-performance materials, makes them ideal for handling the forces of docking in busy ports or marinas. The arc fender not only reduces the risk of costly repairs but also extends the lifespan of both vessels and docking systems. Whether you are dealing with high-traffic ports or recreational docks, the Tonly Arch rubber fender provides reliable and efficient protection, contributing to overall maritime safety.

Exploring Tonly's Superior Fender Solutions: Cylindrical, D Type, and W Type Rubber FendersJune 13, 2023When it comes to ensuring the safety and longevity of both vessels and marine structures, choosing the right fender system is crucial. Fenders act as the first line of defense, absorbing impacts and m...view

Exploring Tonly's Superior Fender Solutions: Cylindrical, D Type, and W Type Rubber FendersJune 13, 2023When it comes to ensuring the safety and longevity of both vessels and marine structures, choosing the right fender system is crucial. Fenders act as the first line of defense, absorbing impacts and m...view The Material Characteristics of UHMWPE FendersSeptember 24, 2025UHMWPE fenders use ultra-high molecular weight polyethylene (UHMWPE) material, which has been widely used in the field of ship protection due to its excellent performance. Compared with traditional in...view

The Material Characteristics of UHMWPE FendersSeptember 24, 2025UHMWPE fenders use ultra-high molecular weight polyethylene (UHMWPE) material, which has been widely used in the field of ship protection due to its excellent performance. Compared with traditional in...view Stability of D-type rubber fenderDecember 16, 2024The quality of D-type rubber fenders always restricts production and use, interferes with docking and the safety of ship drivers, and affects the schedule of production ships. This is not an accidenta...view

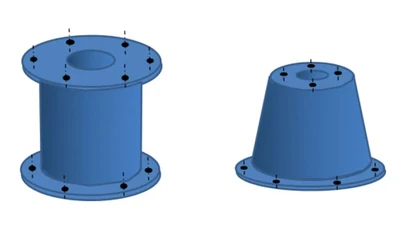

Stability of D-type rubber fenderDecember 16, 2024The quality of D-type rubber fenders always restricts production and use, interferes with docking and the safety of ship drivers, and affects the schedule of production ships. This is not an accidenta...view Rubber fenders with fender panelsDecember 16, 2024A fender panel is a frame made primarily of steel, which is fixed to the front of a rubber fender to lower the average face pressure. A rubber fender with a panel has the disadvantages of complex desi...view

Rubber fenders with fender panelsDecember 16, 2024A fender panel is a frame made primarily of steel, which is fixed to the front of a rubber fender to lower the average face pressure. A rubber fender with a panel has the disadvantages of complex desi...view