When it comes to the protection of boats and other maritime vessels, the installation of a boat side rubber fender is crucial. These fenders serve as buffers between a boat and a dock, ensuring the safety and integrity of both the vessel and the harbor infrastructure. Proper installation of these fenders not only extends the lifespan of the boat but also enhances the safety of all maritime operations. In this guide, we will walk you through the essential steps and considerations needed for the optimal configuration of boat side rubber fenders, ensuring maximum protection for your vessel.

Boat side rubber fenders play a vital role in preventing damage to a vessel during docking and mooring activities. They are typically installed along the sides of the boat, particularly near the areas most likely to come in contact with docks, piers, or other boats. When a boat docks or comes alongside a platform, the rubber fender acts as a cushion, absorbing the impact and reducing the risk of scratches, dents, or other forms of structural damage. The Tonly boat side rubber fender offers an efficient solution for this, with its durability and performance designed to withstand harsh marine environments.

Fenders come in various sizes, shapes, and materials, but the primary purpose remains the same: protecting your vessel from collisions. The Tonly boat side rubber fender is designed to ensure that the boat remains safe during mooring, providing a soft yet firm barrier that cushions the vessel. Installing the right type of fender in the proper position is essential to prevent damage from both the immediate impact and prolonged exposure to environmental factors like waves and tides.

Selecting the appropriate boat side rubber fender depends on several factors, including the size and type of boat, the docking environment, and the anticipated conditions during operation. The Tonly rubber fender is versatile, offering a range of sizes and specifications suitable for various types of boats, including tugboats, yachts, and larger commercial vessels. When choosing a fender, it's important to consider factors such as the vessel's weight, the type of docking conditions it will face, and the specific areas of the boat that require protection.

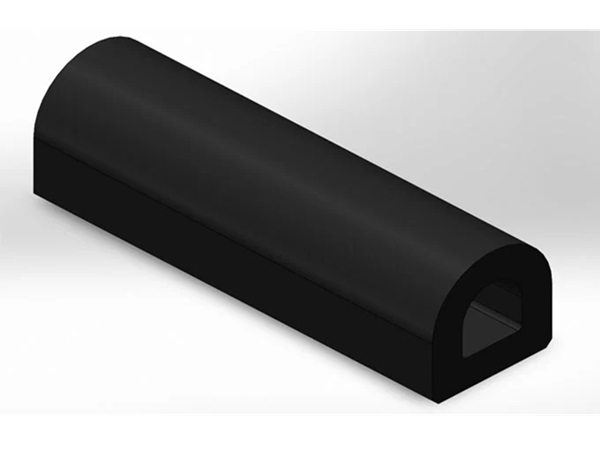

The shape of the fender also plays an important role in ensuring maximum coverage and impact absorption. Tonly's boat side rubber fenders come in different designs, including cylindrical, square, and D-shaped profiles, allowing you to customize the fit according to your vessel's needs. Choosing a fender that fits the shape of your boat's hull will enhance its ability to absorb shock and prevent damage from impacts.

Proper installation of boat side rubber fenders is essential to ensure that they perform effectively. First, identify the areas of your vessel that are most susceptible to damage during docking. These are typically the sides of the boat where it comes into contact with the dock, piers, or other vessels. The Tonly boat side rubber fender can be installed along these areas, securing it firmly in place to absorb shock during impact.

Start by cleaning the surface of the hull where the fender will be mounted. Any dirt, salt, or debris should be removed to ensure a secure fit. Next, choose the appropriate mounting method. Tonly boat side rubber fenders are often equipped with pre-drilled holes for easy installation, allowing you to either bolt or screw the fender into place. It's essential to use high-quality, marine-grade fasteners that can withstand exposure to saltwater and other harsh conditions.

The placement of the fender is also important. Ensure that the fender is positioned at the right height to provide maximum coverage for the vulnerable areas of your boat. It's recommended to install fenders on both sides of the vessel, particularly in areas prone to frequent contact with docks or other boats.

When it comes to protecting your vessel during docking, you may also consider other types of docking solutions, such as steel or foam-based fenders. Below is a comparison table highlighting the key differences between boat side rubber fenders and other common fender types:

Feature | Boat Side Rubber Fender | Steel Fender | Foam Fender |

Durability | High - resistant to UV, saltwater, and wear | Moderate - susceptible to corrosion | Low - can degrade over time in harsh conditions |

Flexibility | Excellent - conforms to boat shape | Rigid - may not fit all boat shapes | Moderate - compresses on impact |

Impact Absorption | High - absorbs shock efficiently | Low - limited shock absorption | Moderate - absorbs impact, but not as well as rubber |

Maintenance | Low - minimal upkeep required | High - requires regular maintenance | Moderate - needs to be checked regularly |

Cost | Moderate - affordable for most vessel sizes | High - often more expensive | Low - affordable but less durable |

As shown in the comparison, boat side rubber fenders offer a balanced combination of durability, impact absorption, and low maintenance compared to steel and foam options. Their ability to provide excellent protection across a range of vessel types makes them a popular choice among boat owners.

Proper installation of a boat side rubber fender is crucial to ensuring the safety and longevity of your vessel. By selecting the right type of fender and installing it correctly, you can protect your boat from damage caused by docking and collisions. Tonly's boat side rubber fenders provide a reliable and durable solution, designed to withstand harsh maritime conditions while offering optimal impact absorption. Whether you own a tugboat, yacht, or commercial vessel, ensuring the proper configuration of your fenders is an essential step in safeguarding your investment.

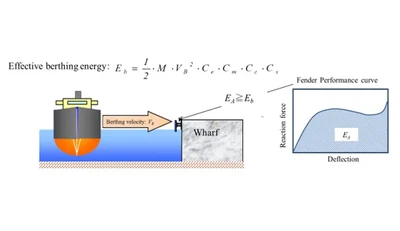

The role of rubber fenders part 1December 16, 2024A rubber fender is a shock absorber installed on a wharf to absorb the berthing energy of a vessel. Timber and old tires were used as shock absorbers until the first rubber fenders were developed in t...view

The role of rubber fenders part 1December 16, 2024A rubber fender is a shock absorber installed on a wharf to absorb the berthing energy of a vessel. Timber and old tires were used as shock absorbers until the first rubber fenders were developed in t...view Diffusivity of vulcanising agents in rubber fendersDecember 16, 2024Rubber fenders in the vulcanising agent diffusion due to the solubility of rubber, so in and between the two phases of the system, the vulcanising agent diffusion occurs migration, at a certain temper...view

Diffusivity of vulcanising agents in rubber fendersDecember 16, 2024Rubber fenders in the vulcanising agent diffusion due to the solubility of rubber, so in and between the two phases of the system, the vulcanising agent diffusion occurs migration, at a certain temper...view All you need to know about marine rubber fenders?December 16, 2024What exactly are marine rubber fenders? For the ordinary person, it may seem weird to have so many weird-looking shapes hovering beside a port or harbour, unclear of what they are for. Even when a pe...view

All you need to know about marine rubber fenders?December 16, 2024What exactly are marine rubber fenders? For the ordinary person, it may seem weird to have so many weird-looking shapes hovering beside a port or harbour, unclear of what they are for. Even when a pe...view Three common causes of damage to rubber fendersDecember 16, 20241. Ship overloadedThis kind of damage often occurs in rubber fenders, especially some old rubber fenders, which often crack at the weak points of the structure. The cracks are generally along the leng...view

Three common causes of damage to rubber fendersDecember 16, 20241. Ship overloadedThis kind of damage often occurs in rubber fenders, especially some old rubber fenders, which often crack at the weak points of the structure. The cracks are generally along the leng...view