At the same vulcanisation speed, general purpose rubber is fastest with natural rubber, followed by isoprene rubber, butadiene rubber, latex polybutadiene rubber and styrene butadiene rubber. Slow vulcanising rubbers using reduced sulphur and increased accelerators can be matched to natural rubber at the same vulcanising speed. In general, for the same vulcanisation speed, natural rubber is a high sulphur low accelerator, SBR is a low sulphur high accelerator and butadiene rubber is in between. The difference in vulcanisation speed of rubber is highly relevant to its molecular structure.

The different vulcanisation systems of natural rubber and chloroprene and butyl rubber are used together. Although the processing performance of the system can be improved, the performance of the vulcanised rubber obtained is below the average due to insufficient co-vulcanisation performance and satisfactory performance cannot be obtained. Co-vulcanisation with natural rubber can be improved by halogenating or increasing the unsaturation of butyl rubber. Suitable curing agents for natural rubber and neoprene are aldehydes, and the properties vary in a linear fashion. From the actual production, and with rubber co-vulcanization and dispersion inseparable.

The more uniform the dispersion between the materials of rubber fenders, the better the physical properties of vulcanisation, but most of the rubber is not uniformly dispersed, due to the different degrees of vulcanisation between the two phases, the interface between different rubber can cross-link, grafting and other factors, will have a decisive impact on the physical properties of vulcanised rubber. The reason for the deviation in the degree of vulcanisation between the two phases of the joint rubber is the solubility of the vulcanised rubber, which is added to the conventional formulation in greenhouse conditions in a dose close to the over-conserved or conserved state. In the vulcanisation temperature range, the degree of vulcanisation is not uniform between the two phases of the rubber due to the difference in solubility between the two phases, the uneven distribution of the vulcanising agent between the two phases, or the concentration difference.

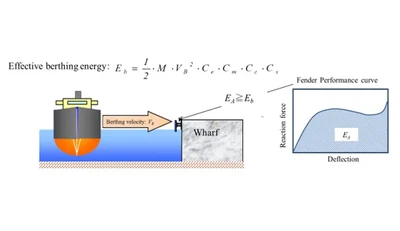

The role of rubber fenders part 1December 16, 2024A rubber fender is a shock absorber installed on a wharf to absorb the berthing energy of a vessel. Timber and old tires were used as shock absorbers until the first rubber fenders were developed in t...view

The role of rubber fenders part 1December 16, 2024A rubber fender is a shock absorber installed on a wharf to absorb the berthing energy of a vessel. Timber and old tires were used as shock absorbers until the first rubber fenders were developed in t...view The Material Characteristics of UHMWPE FendersSeptember 24, 2025UHMWPE fenders use ultra-high molecular weight polyethylene (UHMWPE) material, which has been widely used in the field of ship protection due to its excellent performance. Compared with traditional in...view

The Material Characteristics of UHMWPE FendersSeptember 24, 2025UHMWPE fenders use ultra-high molecular weight polyethylene (UHMWPE) material, which has been widely used in the field of ship protection due to its excellent performance. Compared with traditional in...view D Type Rubber Fenders with Fender FrameDecember 16, 2024view

D Type Rubber Fenders with Fender FrameDecember 16, 2024view Understanding the Value and Applications of Dock Rubber FenderOctober 17, 2024Dock Rubber Fenders are essential components for ship docking and port protection, serving as the frontline defense against impacts during vessel mooring. With the continuous growth of the maritime tr...view

Understanding the Value and Applications of Dock Rubber FenderOctober 17, 2024Dock Rubber Fenders are essential components for ship docking and port protection, serving as the frontline defense against impacts during vessel mooring. With the continuous growth of the maritime tr...view