The marine rubber fender is a very important maintenance item in the ship's post. However, all ships sailing must be equipped with marine fenders, so as to ensure the personal safety of the personnel on the ship.The following introduces the issues that should be paid attention to in the whole process of application of rubber fenders.

At ordinary times, pay attention to check whether the fender is damaged, and whether the standard air pressure is normal.Whether there are sharp objects on the surface touched by the fender rope, attention should be paid to prevent damage to the rubber fender. The place where the rubber fender is stored should avoid the pyrogen, and not place it in a place with higher temperature.

The rubber fender should avoid acid, alkali and alkaline substances and pay attention to its cleanliness.

Please note: Rubber fenders often need to be in contact with corrosive seawater. The rubber formula contains antioxidants and anti-ozone layer, which can protect the rubber from the oxidation and degradation of ultraviolet rays and ozone, so special maintenance is not required.

The Material Characteristics of UHMWPE FendersSeptember 24, 2025UHMWPE fenders use ultra-high molecular weight polyethylene (UHMWPE) material, which has been widely used in the field of ship protection due to its excellent performance. Compared with traditional in...view

The Material Characteristics of UHMWPE FendersSeptember 24, 2025UHMWPE fenders use ultra-high molecular weight polyethylene (UHMWPE) material, which has been widely used in the field of ship protection due to its excellent performance. Compared with traditional in...view Cylindrical Rubber Fender & Dock: The Guardian of Marine SafetyOctober 17, 2024In the bustling world of maritime operations, the safety of vessels and docks is paramount. Enter the Cylindrical Rubber Fender & Dock—a robust protector designed to absorb the shocks and stresse...view

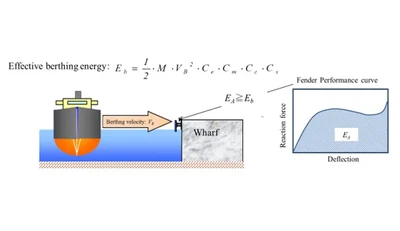

Cylindrical Rubber Fender & Dock: The Guardian of Marine SafetyOctober 17, 2024In the bustling world of maritime operations, the safety of vessels and docks is paramount. Enter the Cylindrical Rubber Fender & Dock—a robust protector designed to absorb the shocks and stresse...view The role of rubber fenders part 1December 16, 2024A rubber fender is a shock absorber installed on a wharf to absorb the berthing energy of a vessel. Timber and old tires were used as shock absorbers until the first rubber fenders were developed in t...view

The role of rubber fenders part 1December 16, 2024A rubber fender is a shock absorber installed on a wharf to absorb the berthing energy of a vessel. Timber and old tires were used as shock absorbers until the first rubber fenders were developed in t...view Requirements for the construction of rubber fendersDecember 16, 20241. All construction teams must follow the various management plans of the project department,comply with management,and achieve safe production and civilized construction.2. On-site construction worke...view

Requirements for the construction of rubber fendersDecember 16, 20241. All construction teams must follow the various management plans of the project department,comply with management,and achieve safe production and civilized construction.2. On-site construction worke...view