The quality of D-type rubber fenders always restricts production and use, interferes with docking and the safety of ship drivers, and affects the schedule of production ships. This is not an accidental operation management problem. In order to solve these problems, it is first necessary to analyze and study the best measures for fender design and material manufacturing. In the following, we hope to conduct an in-depth discussion on its design, manufacturing and use, and further strengthen the quality selection and decision-making awareness of D-type rubber fenders.

According to the conditions, the rubber D-type rubber fender vulcanization process can be divided into room temperature vulcanization and low temperature vulcanization. Low temperature vulcanization can be used for vulcanized film products, soaking it in a carbon disulfide solution containing 2% to 5% sulfur chloride, and then washing and drying. When vulcanized at room temperature, room temperature vulcanized cement (mixed rubber solution) is used for repair, bicycle inner pipe joints, etc. Hot vulcanization is a method of vulcanizing rubber products. According to different vulcanization media and vulcanization methods, thermal vulcanization can be divided into direct vulcanization, indirect vulcanization and aeration vulcanization.

Direct vulcanization is to put the product directly into hot water or steam medium vulcanization. Indirect vulcanization, the product is vulcanized in hot gas, usually used for some products with strict appearance. For mixed gas vulcanization, air vulcanization is carried out first, followed by direct steam vulcanization. This method overcomes the shortcomings of steam vulcanization, affecting the appearance of the product, and the shortcomings of long-term thermal curing due to slow heat transfer and easy aging of hot air.

The spacing and height of the D-type rubber fenders are very important. It must be ensured that the ship will not directly contact the pier wall at the most unfavorable berth angle allowed by the rope, and that the ship can safely rely on different tidal water levels and different air currents, mooring equipment It is very suitable for docking ships of different tonnages.

Boat Side Rubber Fender Installation Guide: How to Ensure Optimal ConfigurationDecember 17, 2025When it comes to the protection of boats and other maritime vessels, the installation of a boat side rubber fender is crucial. These fenders serve as buffers between a boat and a dock, ensuring the sa...view

Boat Side Rubber Fender Installation Guide: How to Ensure Optimal ConfigurationDecember 17, 2025When it comes to the protection of boats and other maritime vessels, the installation of a boat side rubber fender is crucial. These fenders serve as buffers between a boat and a dock, ensuring the sa...view Three common causes of damage to rubber fendersDecember 16, 20241. Ship overloadedThis kind of damage often occurs in rubber fenders, especially some old rubber fenders, which often crack at the weak points of the structure. The cracks are generally along the leng...view

Three common causes of damage to rubber fendersDecember 16, 20241. Ship overloadedThis kind of damage often occurs in rubber fenders, especially some old rubber fenders, which often crack at the weak points of the structure. The cracks are generally along the leng...view Diffusivity of vulcanising agents in rubber fendersDecember 16, 2024Rubber fenders in the vulcanising agent diffusion due to the solubility of rubber, so in and between the two phases of the system, the vulcanising agent diffusion occurs migration, at a certain temper...view

Diffusivity of vulcanising agents in rubber fendersDecember 16, 2024Rubber fenders in the vulcanising agent diffusion due to the solubility of rubber, so in and between the two phases of the system, the vulcanising agent diffusion occurs migration, at a certain temper...view Performance of rubber fendersDecember 16, 2024In the design process, the performance of rubber fenders is considered in terms of deflection-reaction force characteristics in compression and the energy absorption calculated from these characterist...view

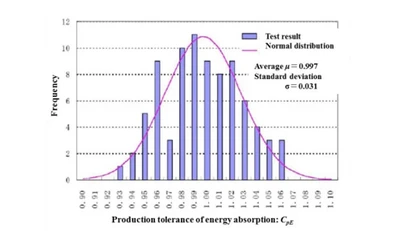

Performance of rubber fendersDecember 16, 2024In the design process, the performance of rubber fenders is considered in terms of deflection-reaction force characteristics in compression and the energy absorption calculated from these characterist...view