The primary function of a W rubber fender is to absorb the energy of an impact between a vessel and a dock, buoy, or another ship, ensuring that the boat's hull remains protected from damage. This is particularly crucial in harsh maritime environments where collisions are frequent. In this article, we delve into the science of how W rubber fenders effectively absorb impact, their material properties, and design features that make them an essential part of docking and mooring operations.

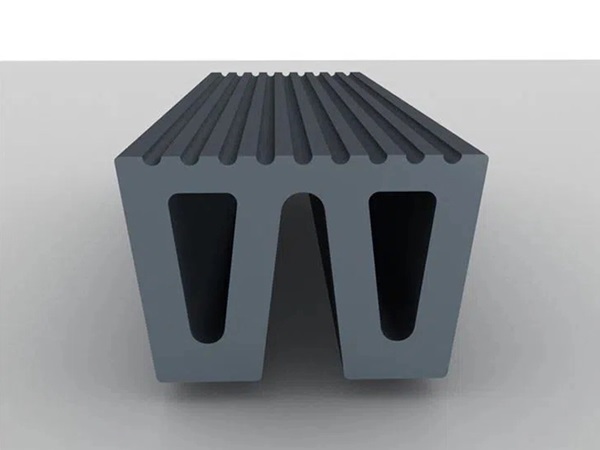

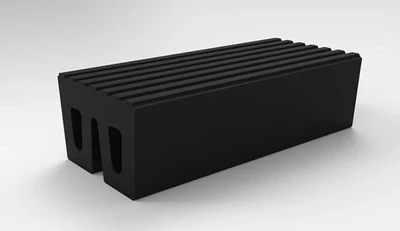

The design of the W rubber fender is central to its ability to absorb impact. Its unique W-shape offers a combination of flexibility and durability, making it ideal for a variety of docking conditions. When a vessel makes contact with the fender, the rubber compresses, and the energy from the impact is dissipated across the fender's surface. This compression absorbs the shock and reduces the force that would otherwise be transferred to the hull of the boat. The Tonly W rubber fender is designed to withstand the energy of both slow and fast impacts, making it versatile enough for use in different docking scenarios, from gentle mooring in calm harbors to rough docking in busy ports.

The structure of the W rubber fender allows it to handle large amounts of pressure while maintaining its shape, ensuring that the impact is spread evenly and efficiently. This helps to minimize localized damage to both the boat and the dock, as well as preventing excessive wear on the fender itself. Furthermore, the Tonly W rubber fender is made from high-quality materials that resist deterioration, such as UV exposure and saltwater, making it a long-lasting solution in harsh marine environments.

The material composition of the W rubber fender plays a significant role in its ability to absorb impact. These fenders are typically made from high-performance synthetic rubbers like EPDM (Ethylene Propylene Diene Monomer) or SBR (Styrene-Butadiene Rubber), which are known for their elasticity, resilience, and resistance to environmental factors such as UV radiation, ozone, and seawater. The rubber's ability to stretch and compress under load ensures that it can withstand repeated impacts without losing its protective qualities.

When a W rubber fender is compressed upon impact, the rubber undergoes a temporary deformation and then returns to its original shape once the pressure is released. This resilience means the fender will continue to provide reliable shock absorption over time. In addition, the rubber's inherent flexibility allows the W rubber fender to adjust to the contours of the vessel's hull, ensuring an even distribution of force across the contact area. This reduces the likelihood of point-specific damage, which can occur if the force is not properly distributed.

When choosing the best fender for your vessel, it's important to understand how W rubber fenders compare to other commonly used fender types. Below is a comparison table that highlights the unique features of W rubber fenders versus traditional cylindrical fenders and foam fenders:

Feature | W Rubber Fender | Cylindrical Fender | Foam Fender |

Impact Absorption | High – absorbs energy efficiently through compression | Moderate – limited compression and shock absorption | Moderate – compresses but not as efficiently as rubber |

Durability | High – resistant to UV, saltwater, and wear | Moderate – can degrade over time | Moderate – can lose buoyancy and structural integrity over time |

Flexibility | Excellent – adapts to the shape of the vessel and distributes impact evenly | Low – rigid, less adaptable to different vessel shapes | Moderate – can compress but is not as flexible as rubber |

Installation | Easy – can be installed on various vessel shapes | Easy – can be mounted along boat sides | Moderate – requires careful maintenance and inspections |

Maintenance | Low – requires minimal upkeep | Low – easy to maintain but can show wear over time | Moderate – needs periodic checks for damage and performance |

From the comparison, it's clear that W rubber fenders provide superior impact absorption, durability, and flexibility when compared to other fender types. The W-shape design is ideal for vessels that require a high level of protection, especially in dynamic and challenging docking environments.

The distinctive W-shape of the Tonly W rubber fender is designed for optimal shock absorption and performance. The design allows for an increased contact surface area between the fender and the vessel, enhancing the fender's ability to absorb more energy from an impact. The multiple faces of the W-shape contribute to the fender's flexibility, enabling it to distribute the impact force evenly over a larger area.

In addition to its shock-absorbing benefits, the W-shape provides greater stability and prevents the fender from sliding off the vessel during mooring. The two wings on either side of the W-shape provide additional support and ensure that the fender remains in place, providing continuous protection for the boat. This design is particularly useful in situations where there are heavy impacts or irregular docking conditions, such as when vessels are subjected to strong tides or high winds.

In conclusion, W rubber fenders are crucial for protecting vessels from the potential damage caused by docking and mooring. Their material properties, unique W-shape design, and ability to absorb impact efficiently make them an indispensable part of any maritime operation. By dispersing impact energy over a larger surface area, these fenders minimize damage to both the boat and the dock, ensuring that your vessel remains safe even in rough conditions. Whether you're dealing with a small yacht or a large commercial ship, Tonly's W rubber fenders provide reliable and long-lasting protection for your vessel, ensuring that it stays in top condition for years to come.

Cylindrical Rubber Fender & Dock: The Guardian of Marine SafetyOctober 17, 2024In the bustling world of maritime operations, the safety of vessels and docks is paramount. Enter the Cylindrical Rubber Fender & Dock—a robust protector designed to absorb the shocks and stresse...view

Cylindrical Rubber Fender & Dock: The Guardian of Marine SafetyOctober 17, 2024In the bustling world of maritime operations, the safety of vessels and docks is paramount. Enter the Cylindrical Rubber Fender & Dock—a robust protector designed to absorb the shocks and stresse...view A Kind of Full-Rotation TugboatDecember 16, 2024The full-rotation tugboat comprises a boat body, a main engine and a propeller, wherein circular rubber fenders are installed at a head, stern and middle part of the boat body;a V-shaped dead wood is ...view

A Kind of Full-Rotation TugboatDecember 16, 2024The full-rotation tugboat comprises a boat body, a main engine and a propeller, wherein circular rubber fenders are installed at a head, stern and middle part of the boat body;a V-shaped dead wood is ...view W-type rubber fender performance advantagesDecember 16, 2024W-type rubber fender application: usually fixed on the steel structure shock-proof board with bolts and nuts, there are exceptions, it is directly fixed on the cement wall of the wharf, shock-proof wo...view

W-type rubber fender performance advantagesDecember 16, 2024W-type rubber fender application: usually fixed on the steel structure shock-proof board with bolts and nuts, there are exceptions, it is directly fixed on the cement wall of the wharf, shock-proof wo...view Five types of popular tug boat fendersDecember 16, 2024Tug boat fenders are high abrasion resistance rubber fenders used to protect the vessel and the other surface during contact. Boat fenders are also known as boat bumpers, rubber fenders and marine fen...view

Five types of popular tug boat fendersDecember 16, 2024Tug boat fenders are high abrasion resistance rubber fenders used to protect the vessel and the other surface during contact. Boat fenders are also known as boat bumpers, rubber fenders and marine fen...view