Rubber fenders in the vulcanising agent diffusion due to the solubility of rubber, so in and between the two phases of the system, the vulcanising agent diffusion occurs migration, at a certain temperature is usually transferred to the vulcanising agent solubility of the rubber phase, after reaching the distribution coefficient to reach an equilibrium state. The diffusion of the vulcanising agent and other compatibilisers is very fast and the concentration difference in the same rubber can be eliminated in a short time.

In other words, there is a close relationship between good and bad rubber fenders with materials and the vulcanisation system. When two kinds of rubber together, if the vulcanization system used by the two is the same or with co-vulcanization, then for the same vulcanization system, the solubility of the vulcanizing agent and the diffusion of differences. When vulcanising, the vulcanising agent favours the rubber with the greater diffusion concentration, so the vulcanisation rate is accelerated. As a result, two rubbers, over-sulphurised or un-sulphurised, co-exist, forming an inhomogeneous vulcanisation between the heterogeneous phases, and in order to improve the ozone resistance of the diene-based rubber with which the physical properties of the rubber are reduced, the mixture is substantially improved, and the addition of sulphur also improves the fatigue and flexural resistance of the combined system.

In addition, the addition of a third component to the compounding system or an increase in the degree of unsaturation, for example from 1.8% to 18% for isoprene, can improve the compounding properties of diene rubbers. Alternatively, the introduction of unsaturated groups into the acrylic rubber backbone allows co-vulcanisation with sulphur. By using hydroxymethylated resins and nitrile rubber in combination, products with high tensile strength and high hardness can be obtained. Chemical reactions in rubber are also used. Natural rubber and butadiene rubber are combined with a cross-linking reaction, natural rubber and bupropylene rubber without a cross-linking reaction. There is also a cross-linking reaction in the combined system of polyurethane rubber and bupropylene rubber.

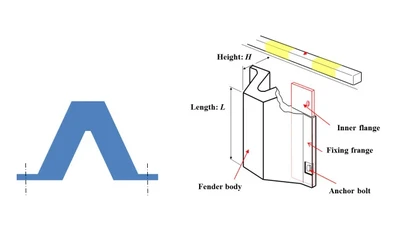

Rubber fenders without fender panelsDecember 16, 2024V-type rubber fenders are considered as rubber fenders without fender panels. A V-type rubber fender has a V-shaped cross section with steel plates embedded in the fixing flange portion for installati...view

Rubber fenders without fender panelsDecember 16, 2024V-type rubber fenders are considered as rubber fenders without fender panels. A V-type rubber fender has a V-shaped cross section with steel plates embedded in the fixing flange portion for installati...view Cost strategy of marine rubber fenderDecember 16, 2024With the development of China's shipping industry, the demand for marine and terminal fenders continues to increase. Among them, marine rubber fenders are the most widely used for toughness and im...view

Cost strategy of marine rubber fenderDecember 16, 2024With the development of China's shipping industry, the demand for marine and terminal fenders continues to increase. Among them, marine rubber fenders are the most widely used for toughness and im...view How to choose the right raw material for rubber fenders?December 16, 2024The choice of rubber fender material is a technical one, allowing the selection of a variety of raw rubber and compounding agent varieties and amounts suitable for the mixing, rolling, moulding and vu...view

How to choose the right raw material for rubber fenders?December 16, 2024The choice of rubber fender material is a technical one, allowing the selection of a variety of raw rubber and compounding agent varieties and amounts suitable for the mixing, rolling, moulding and vu...view Understanding the Value and Applications of Dock Rubber FenderOctober 17, 2024Dock Rubber Fenders are essential components for ship docking and port protection, serving as the frontline defense against impacts during vessel mooring. With the continuous growth of the maritime tr...view

Understanding the Value and Applications of Dock Rubber FenderOctober 17, 2024Dock Rubber Fenders are essential components for ship docking and port protection, serving as the frontline defense against impacts during vessel mooring. With the continuous growth of the maritime tr...view