Selecting the appropriate rubber fenders for marine applications requires understanding how different designs perform under specific conditions. While cylindrical rubber fenders offer excellent all-around performance, other types like D, W, and square fenders excel in specialized applications. This comprehensive guide compares these major fender types to help you make an informed decision for your vessel or dock.

Before diving into comparisons, it's essential to understand what each fender type brings to marine protection:

The versatile workhorse of marine protection, cylindrical fenders feature a simple, round design that provides consistent performance across various applications. Their symmetrical shape allows for multi-directional impact absorption and easy rotation for even wear distribution.

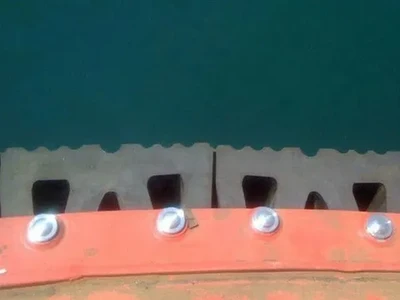

Characterized by their distinctive "D" shape with a flat mounting surface, these fenders offer excellent energy absorption in a compact design. Their flat back allows for secure mounting against dock walls or vessel sides.

These fenders feature a double-arch design that provides higher energy absorption relative to their size. The "W" shape creates additional deflection capacity, making them suitable for applications with significant berthing energy.

With their flat contact surfaces, square fenders provide maximum contact area and are particularly effective for parallel berthing applications where large surface coverage is needed.

Fender Type | Energy Absorption Efficiency | Reaction Force Profile | Best For |

Cylindrical | High, with smooth progressive resistance | Lower initial reaction, builds progressively | General purpose applications, variable impact angles |

D-Type | Very high per unit size | Higher initial reaction force | High-energy berthing where space is limited |

W-Type | Highest among standard types | Progressive, with excellent energy distribution | Large vessels, high-energy ports, heavy impacts |

Square | Moderate to high (depends on compression) | Higher reaction due to flat surface contact | Parallel berthing, situations requiring maximum contact area |

Data based on standard marine fender performance curves and industry testing.

Cylindrical boat fenders shine in installation simplicity. Their symmetrical design allows for multiple mounting options and easy rotation to distribute wear evenly. This translates to lower maintenance costs and longer service intervals.

D-type fenders, while offering secure flat-back mounting, require precise alignment and cannot be rotated for even wear distribution. Their specialized shape may also limit mounting flexibility in some applications.

W-type fenders typically require professional installation due to their complex stress distribution patterns. Their specialized design often means higher installation costs but excellent long-term performance in demanding environments.

Square fenders offer straightforward flat-surface mounting but lack the self-aligning features of cylindrical designs. Their corners can experience uneven wear in certain applications.

The simplicity of cylindrical marine fenders contributes to their exceptional durability. Without complex internal structures or stress concentration points, they typically offer longer service life with minimal degradation in performance.

's cylindrical rubber fenders benefit from homogeneous construction that withstands environmental stresses uniformly.

D-type and W-type fenders, while durable, may experience stress concentration at design transitions. Square fenders can suffer corner wear in high-traffic applications, potentially reducing their effective lifespan.

For busy commercial ports handling diverse vessel types, cylindrical fenders offer unmatched versatility. Their ability to accommodate different berthing angles and vessel sizes makes them ideal for multi-use docks. W-type fenders may be preferred for dedicated terminals serving consistently large vessels.

Cylindrical boat fenders are typically the best choice for recreational marinas due to their:

Easy installation on floating docks

Gentle contact with various hull types

Cost-effectiveness for multiple slip configurations

Minimal maintenance requirements

For offshore applications where space is constrained and impacts can be severe, D-type and W-type fenders often provide higher energy absorption in compact designs. However, cylindrical marine fenders remain excellent for general supply vessel interfaces and areas requiring multi-directional protection.

High-frequency operations benefit from the durability and low maintenance of cylindrical rubber fenders. Their ability to withstand constant impacts without performance degradation makes them cost-effective for terminals with frequent docking operations.

Most Economical: Cylindrical fenders typically offer the lowest initial cost per unit of protection

Premium Investment: W-type and specialized D-type fenders command higher initial prices due to complex manufacturing

When considering total cost of ownership, cylindrical fenders often provide superior value through:

Longer service life due to even wear distribution

Lower maintenance costs from simple design and easy inspection

Reduced replacement frequency thanks to durable homogeneous construction

Flexibility that avoids specialized replacement part requirements

Cost Factor | Cylindrical | D-Type | W-Type | Square |

Installation Complexity | Low | Medium | High | Low-Medium |

Maintenance Frequency | Low | Medium | Medium | Medium |

Expected Service Life | 15-25 years | 10-20 years | 15-25 years | 10-20 years |

Replacement Flexibility | High (standard sizing) | Medium | Low (often custom) | Medium |

Unlike flat-backed designs, cylindrical marine fenders provide equal protection regardless of impact angle. This is particularly valuable in locations with tidal variations, currents, or multiple vessel types.

From simple rope lashings to advanced chain systems, cylindrical designs accommodate diverse mounting requirements without specialized hardware.

The circular cross-section of cylindrical rubber fenders ensures consistent performance as they compress, providing predictable energy absorption across their full deflection range.

Tonly's cylindrical fenders have demonstrated reliability across global applications, from tropical ports to Arctic facilities, thanks to their resistance to environmental stresses and uniform material properties.

Multiple vessel types using the same berth

Limited budget with need for reliable protection

Situations requiring easy maintenance and inspection

Applications where installation flexibility is valuable

Environments with variable impact angles

Extremely high energy absorption requirements in constrained spaces (consider W-type)

Dedicated berths for specific large vessel types (may benefit from custom designs)

Applications requiring maximum flat surface contact (square might be preferable)

Specialized mounting situations where flat-back designs offer advantages

With over 60 years of rubber engineering experience, Tonly has refined cylindrical rubber fender technology to deliver optimal performance. Our advantages include:

Advanced Material Science: Proprietary rubber compounds optimized for marine environments

Precision Manufacturing: Consistent quality through controlled vulcanization processes

Comprehensive Testing: Rigorous performance validation against international standards

Technical Support: Expert guidance on selection, installation, and maintenance

Our cylindrical fenders undergo extensive quality control, including:

Material homogeneity testing

Compression and recovery validation

Environmental resistance certification

Real-world performance monitoring

What vessel types and sizes will use the facility?

Multiple types → Cylindrical fenders

Single large vessel type → Consider specialized designs

What are your maintenance capabilities and budget?

Limited maintenance resources → Cylindrical fenders

Professional maintenance teams → More flexibility in choice

How critical is installation speed and simplicity?

Quick installation needed → Cylindrical fenders

Complex, engineered installations → All options possible

What is your total budget including long-term costs?

Balanced initial and ongoing costs → Cylindrical fenders

Maximum performance regardless of cost → Premium specialized types

While each fender type has its place in marine protection, cylindrical rubber fenders offer the most balanced combination of performance, durability, and value for the majority of applications. Their versatility, ease of maintenance, and cost-effectiveness make them the preferred choice for ports, marinas, and offshore facilities worldwide.

At Tonly, we specialize in manufacturing high-quality cylindrical marine fenders that deliver reliable protection across diverse operating conditions. Our engineering team can help you determine whether cylindrical fenders are optimal for your specific needs or if a specialized design might offer advantages.

D Type Rubber Fenders with Fender FrameDecember 16, 2024view

D Type Rubber Fenders with Fender FrameDecember 16, 2024view A Kind of Full-Rotation TugboatDecember 16, 2024The full-rotation tugboat comprises a boat body, a main engine and a propeller, wherein circular rubber fenders are installed at a head, stern and middle part of the boat body;a V-shaped dead wood is ...view

A Kind of Full-Rotation TugboatDecember 16, 2024The full-rotation tugboat comprises a boat body, a main engine and a propeller, wherein circular rubber fenders are installed at a head, stern and middle part of the boat body;a V-shaped dead wood is ...view The Science Behind W Rubber Fenders: How They Absorb ImpactDecember 17, 2025The primary function of a W rubber fender is to absorb the energy of an impact between a vessel and a dock, buoy, or another ship, ensuring that the boat's hull remains protected from damage. This...view

The Science Behind W Rubber Fenders: How They Absorb ImpactDecember 17, 2025The primary function of a W rubber fender is to absorb the energy of an impact between a vessel and a dock, buoy, or another ship, ensuring that the boat's hull remains protected from damage. This...view Characteristics and Applications of Arch Rubber FendersSeptember 24, 2025An arch rubber fender is a type of marine dock rubber fender commonly used in ports and docks. Due to its unique design and exceptional performance, it is widely applied for the berthing protection of...view

Characteristics and Applications of Arch Rubber FendersSeptember 24, 2025An arch rubber fender is a type of marine dock rubber fender commonly used in ports and docks. Due to its unique design and exceptional performance, it is widely applied for the berthing protection of...view