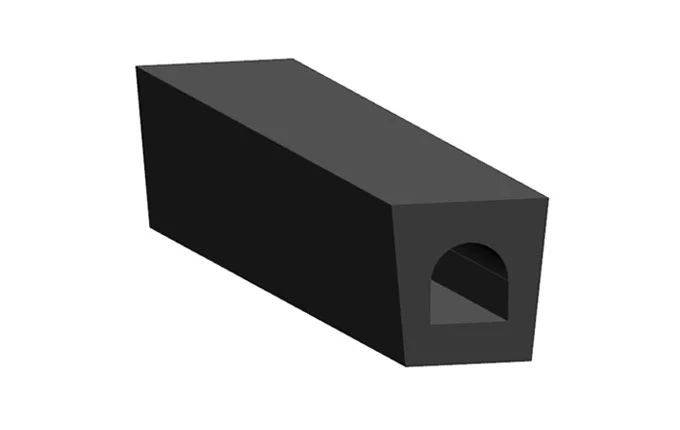

Engineered and manufactured by Tonly, a trusted composite fender manufacturer with decades of expertise, our Trapezoidal Composite Rubber Fender represents the pinnacle of modern berthing protection. This innovative design uniquely combines the exceptional elasticity and energy absorption of high-grade rubber with the superior strength-to-weight ratio and environmental resistance of advanced composite materials. The result is a fender that delivers unmatched durability, cost-effectiveness, and safety for demanding applications in ports, harbors, tugboat operations, and offshore installations. Our commitment as a factory-direct supplier ensures rigorous quality control from material selection to final vulcanization.

The choice of composite materials should be based on the specific environmental conditions and performance requirements.

High-quality rubber combined with advanced polymers or synthetic fibers can provide the best balance of durability and flexibility.

The trapezoidal shape should be optimized to provide the maximum contact area and energy absorption.

The size of the fender should be chosen based on the size and type of vessels it will be protecting, as well as the specific docking conditions.

The fender’s mounting system should be designed for easy installation and replacement, with robust brackets and hardware to ensure secure attachment.

Consideration should be given to the specific dock or quay wall structure to ensure compatibility and optimal performance.

Regular inspections and maintenance are crucial to ensure the fenders remain in good condition and continue to provide effective protection.

The modular design can simplify maintenance tasks, allowing for easy replacement of damaged or worn components.

The use of composite materials increases the fender’s lifespan, reducing the frequency of replacements and overall maintenance costs.

Improved resistance to environmental factors such as UV radiation, saltwater, and temperature fluctuations ensures long-term performance.

While the initial investment may be higher, the long-term savings from reduced maintenance, fewer replacements, and enhanced protection make these fenders a cost-effective choice.

The modular design can also lower installation and replacement costs.

The larger contact area and superior energy absorption capabilities enhance safety for both vessels and dock structures.

Reduced impact forces minimize the risk of damage and associated repair costs.

Trapezoidal composite rubber fenders can be used in a wide range of applications, from small marinas to large commercial ports.

Their customizable design allows them to be tailored to specific needs, ensuring optimal performance in various scenarios.

Choosing Tonly means more than just buying a fender; it’s partnering with a vertically integrated rubber fender factory. With over 60 years of experience, we control the entire process:

In-House Material Lab: Formulating custom rubber compounds and selecting composite materials for optimal performance.

Advanced Manufacturing: Utilizing dedicated vulcanizing presses and automated facilities for consistent, high-quality production.

Quality Certification: Our ISO 9001 certified system guarantees every fender meets stringent global standards.

Global Project Support: From initial design consultation to on-site installation guidance, our team provides end-to-end support.

Need top-quality rubber fenders for boats and docks? Tonly offers premium, durable fenders for exceptional protection. Ideal for commercial or recreational use. Contact us for more details.